Have you ever seen a t-shirt or a mug with a really cool design and wondered how it was made? The design was likely created using sublimation printing. It is a type of digital printing that uses heat to transfer dye onto a surface.

This article will explain what dye sublimation is, the different types of substrates you can use, and the pros and cons of using this printing method. So, whether you're looking to start your own sublimation business or are just curious about this unique printing process, keep reading for all the details!

What is Sublimation Printing?

Sublimation, often known as heat transfer or dye-sublimation printing, is a technique of applying color to a substrate, typically a polymer, through heat. The dye is in the form of a solid, and the heat causes it to change into a gas. This gas penetrates the fabric, fixing the color permanently into it.

In science, sublimation refers to a passage from the solid-state directly to a gas.

Sublimation printing differs from other printing types because it uses a special dye sublimation ink that is of high quality, water-resistant, and doesn't smudge at high temperatures (400°F or 200°C).

The dye is part of the fabric, so there is no flaking or peeling. It also doesn't fade over time, making it a very durable print method.

Direct-to-garment vs. Heat Transfer printers

Two main types of sublimation printers are direct-to-garment and heat transfer paper printers. Direct-to-garment printers are used to print images directly onto the clothing using polymers. On the other hand, heat transfer paper printers can create prints to apply to other surfaces like ceramics or metal, not just polymers.

Dye-sublimation printing is an excellent option for creating customized prints because it's so versatile. You can use it to create designs with lots of details, and the prints are colorful and vibrant. It's also an excellent choice for printing photos since they will retain their quality over time.

We can attribute the rise in popularity of sublimation printing to the fact that it's a very user-friendly printing process, and you can do it at home. It's easy to set up and use for everybody.

The Sublimation Printing Process

The sublimation printing process is a method of printing that uses heat to transfer dye onto a substrate.

The sublimation printing process begins by printing the design on special sublimation paper. When this paper is heated, the dye transforms into a gas and combines with the substrate material. This sublimation (solid to gas) causes the dye to print onto the fabric permanently.

The pressure applied during the printing process helps set the sublimation ink and ensure it will not evaporate away from where you want to print your design. The heat also opens the pores of the fabric, which allows for better absorption of the dye. Once the ink has cooled, it will solidify and become a part of the substrate material.

The outcome of sublimation printing is a high-quality, long-lasting image that will not fade or crack over time. This type of printing is perfect for creating promotional items on cotton t-shirts and mugs. It's also great for selling print-on-demand products or printing signage and banners.

Small batch orders and custom designs are no problem for sublimation printing. This process is also very versatile, as you can use it on various materials. Once mastered, dye sublimation can provide beautiful and durable prints that will last for years.

Sublimation fabrics

You can use this process on various polyester materials containing manufactured polymers, preferably with 100% polyester. Try to have at least 60% polyester fabric (40% cotton). However, you can also sublimate your designs into lycra, nylon spandex, or even ceramics. These are manufactured materials that are good for fixing sublimation dyes.

Unfortunately, it's much harder to sublimate into 100% cotton and other natural fibers as they don't fix the sublimation ink easily unless you use some tricks.

Supplies Required For Dye Sublimation

One of the best things about sublimation printing is that it doesn't require a lot of specialized equipment. Most people already have everything they need to get started.

To sublimate onto a garment or any other item, you will need:

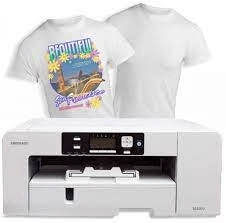

1. Sublimation Printer

A sublimation printer is a particular type of printer that uses heat to transfer dye onto a substrate. While you can use a standard inkjet printer for dye-sublimation, the process is much slower, and the results are not as good.

Sublimation printers are available in desktop and large format models and can cost anything from a few hundred to several thousand dollars.

2. Heat Press

A heat press is a machine that uses heat and pressure to transfer an image onto a substrate. Heat presses are available in various sizes and styles, but the essential thing to consider is the size of the platen, which is the flat heating element.

The platen size will determine the maximum size of the substrate that can be pressed. Heat presses can cost anywhere from a few hundred to several thousand dollars.

3. Mug Clamp and Press (optional)

If you're planning on sublimating onto mugs, you will need a mug clamp and press. These special tools help hold the mug in place during the sublimation process. You can purchase mug clamps and presses separately or as part of a kit.

While you can technically use a sublimation printer and heat press to sublimate onto mugs, using a mug clamp and press is much easier (and less messy).

4. Dye Refills

Dye-sublimation printing uses special sublimation inks, available in refillable cartridges or as dye refills. First, dye refills are a concentrated form of sublimation ink mixed with water to create the sublimation solution.

Dye refills are more economical than sublimation ink cartridges, but they require mixing and measuring. You can store the sublimation solution for future use, but you should use it within six months for the best results.

5. Special Transfer Paper

Sublimation printing uses special sublimation transfer paper. This paper is coated with a sublimation dye transferred to the substrate during the sublimation process.

Transfer paper is available in various sizes and styles, including sheets, rolls, and even precut shapes. Sublimation and copy paper are two of the most common transfer paper types, but sublimation-specific papers are also available.

6. Protective Paper

When doing sublimation printing, you must protect your heat press with protective paper. Otherwise, you'll get sublimation ink on your press, under the fabric you are printing on.

Protect the inside of your shirt by putting only one layer of your t-shirt on the press when printing.

7. Raster Image Processor (RIP) Software (optional)

Raster image processor (RIP) software is a special software used to convert images into the format required for sublimation printing. RIP software is not required, but it can be helpful for color correction and other advanced digital printing techniques.

You will need graphic design software if you plan on designing your sublimation prints. Although free options like Canva, GIMP, and Inkscape are available, Adobe Photoshop, InDesign, and Illustrator are the best graphic design software for sublimation printing. They are part of the Adobe Creative Cloud offering.

Types of Fabric You Can Sublimate On

Just about any type of fabric can be sublimated, including cotton, polyester, and even leather. However, some fabrics are better suited for sublimation than others. 100% cotton materials, for example, are not suitable because the dye will not bind to the fabric correctly.

Polyester fabric and ceramic are the best materials for sublimation printing because the dye binds permanently to the fabric or surface and will not fade or wash away. In addition, polyester is a synthetic material that does not shrink, making it a good choice for sublimating onto garments.

Other suitable fabrics include:

- Poly/Cotton blends

- Nylon

- Polymer

- PVC

- Ceramic

Choosing the suitable fabric is important because it will affect the quality of the sublimation print. In general, you should avoid sublimating onto 100% cotton fabrics because the dye will not bind properly, and the results will be subpar.

How To Choose The Right Sublimation Heat Press

When choosing a sublimation heat press, there are a few things to consider:

1. Size

The size of the heat press is crucial because you need to make sure it's big enough to accommodate the items you want to sublimate. You generally want a heat press at least as big as the item you're sublimating.

2. Type

There are two main types of sublimation heat presses: manual and automatic. Manual heat presses require more muscle power but are less expensive than automatic heat presses. Automatic heat presses are faster and easier to use but are also more costly.

3. Features

Some sublimation heat presses include additional features, such as a digital LCD or an automatic timer. These features can be helpful, but they are not essential.

4. Price

Price is always a consideration when purchasing any equipment. Sublimation heat presses range in price from around $100 to $2000+. The price depends on the press's size, type, and features.

A popular heat press for sublimation printing and heat transfer is the Cricut EasyPress.

Pros and Cons of Sublimation Printing

Like any printing process, sublimation printing has pros and cons that you should be aware of before deciding whether it's the right choice for your project.

Pros:

- Creative Freedom: One of the most significant advantages of sublimation printing is the creative freedom it offers. With sublimation, you can print your design on various materials, including fabric, ceramic, metal, and even glass. So whether you want a giant pizza printed on your t-shirt or a photo of your dog printed on a coffee mug, sublimation printing can make it happen.

- Long-Lasting: Seeing your favorite shirt slowly fade away after a few washes is one of the most frustrating things about clothes shopping. But with sublimation printing, you don't have to worry about your designs fading over time. Sublimated prints are more resistant to fading than traditional screen prints.

- Vibrant Colours: Because sublimation printing uses dye-based ink, it can produce more vibrant colors than other printing methods. So if you're looking for your design to really pop, sublimation is the way to go.

- Fast and Easy: Sublimation printing is a quick and easy process that doesn't require special skills or training. And because sublimation printers are relatively inexpensive, they're an excellent option for small and home-based businesses.

- Ideal For Small Batch Orders: Sublimation printing is ideal for small batch orders. Unlike screen printing, which requires a minimum order quantity, sublimation can be done on a smaller scale, making it an excellent option for businesses that don't have the need or budget for large print runs.

Cons:

- Only Suitable For Some Materials: One of the main drawbacks of sublimation printing is that it's only suitable for specific materials. To work correctly, you should use artificial fabric such as polyester, polymer, or PVC for sublimation. So if you want to print on 100% cotton materials, sublimation won't be an option.

- White Creasing: Another downside of sublimation printing is that it can sometimes cause white creasing on the material. If an area of a garment is unreachable by the sublimation ink during the printing process, it will result in a white line or crease.

- Requires Specific Equipment: To do sublimation printing, you'll need a sublimation printer, heat press, and sublimation inks. These can be expensive, and sublimation printers are not always easy to find.

Sublimation Printing vs. Heat Transfer Printing

A misconception about sublimation printing is that it's the same as heat transfer printing. But while both sublimation and heat transfer use heat to apply a design to a garment, the two processes are quite different.

Here's a quick rundown of the main differences between sublimation printing and heat transfer printing:

Equipment Requirements and Startup Costs

Sublimation printing requires a sublimation printer, sublimation inks, a heat press, and sublimation paper. Considering that a standard sublimation printer can cost upwards of $1000, sublimation printing can be pretty expensive to get started with. The average startup cost of sublimation printing is between $2500 and $3000.

Heat transfer printing, on the other hand, is a much cheaper printing method to get started with. You can find a decent heat transfer printer for under $500, and the additional equipment you need is relatively inexpensive. The average startup cost of heat transfer printing is between $500 and $1000.

Print Quality

When it comes to print quality, sublimation printing is the clear winner. Thanks to the sublimation inks and printing process, sublimated prints are much more vibrant and color-rich than heat transfer prints. And because sublimation printing uses a dye-based ink, the print will become part of the fabric rather than just sitting on top of it.

On the other hand, heat transfer printing uses an inkjet printer and transfer paper. The heat transfer ink is then moved onto the garment using a heat press. And because the ink is not dye-based, it also doesn't penetrate the fabric, resulting in a less vibrant and less durable print. Heat transfer printing results in getting a print layer on top of your t-shirt and not merging into it.

Material Compatibility

As we mentioned before, sublimation printing is only compatible with certain materials. For sublimation to work, the material must be made of polyester, polymer, or PVC. This limits the types of materials you can use for sublimation.

In contrast, heat transfer printing is compatible with a much wider range of materials. You can do heat transfer on fabrics like cotton, polyester, and leather. So if you're looking to print on various materials, heat transfer might be a better option.

Print Size

One of the benefits of sublimation printing is that you can do it on a smaller scale. This makes sublimation an excellent option for businesses that don't have a large budget for printing.

Heat transfer printing, on the other hand, is better suited for larger prints. This is because heat transfer paper is generally available in larger sizes than sublimation paper. So if you're looking to print on a large format, heat transfer might be a better option.

Speed

Sublimation printing is a reasonably slow printing process. It can take up to 45 seconds to print a single design, and this doesn't even include the time it takes to press the design onto the garment. So if you're looking for a quick and easy printing method, sublimation might not be the best option.

Heat transfer printing is much faster than sublimation printing. Printing a design can take as little as 10 seconds, and the whole process is generally much quicker and easier. So if you're looking for a fast and easy printing method, heat transfer might be a better option.

As you can see, sublimation and heat transfer are two very different printing methods. And while both have pros and cons, choosing the proper printing method for your needs is essential.

Heat transfer might be the best option if you're looking for a quick and easy printing method with no startup costs. But if you're looking for a high-quality print that will last, sublimation might be the better choice.

The Best Printers for Sublimation Printing

You'll need a sublimation printer if you're considering getting into sublimation printing. But with so many sublimation printers on the market, it can be hard to know which one is right for you.

Here are some of the best dye sublimation printers on the market:

1. Epson SureColor F170

The Epson SureColor F170 is a dye-sublimation printer with a compact design, making it perfect for small or home-based businesses. Users simply have to fill the ink tanks with sublimation inks and connect the printer to a computer via USB, just like a regular printer.

The Epson SureColor F170 comes with four 140ml T49M bottles, some of the best sublimation inks on the market. It also comes with accompanying PC and Mac software, making it easy to start with sublimation printing.

2. Sawgrass SG500

The Sawgrass SG500 is a dye sublimation printer designed for small businesses. It is compact and can easily be put on a desk or table. On top of that, the Sawgrass SG500 comes with the company's UHD sublimation inks, Sublisure A4 transfer paper, and Sawgrass software for easy design and printing.

It also has a sublimation printing speed of up to 240 prints per hour, making it one of the fastest sublimation printers on the market.

3. HP Stitch S500

If you're looking for a flexible and efficient sublimation printer, the HP Stitch S500 is a great option. It is made specifically for dye sublimation and can print on various fabrics, including polyester, nylon, and lycra.

The HP Stitch S500 is ideal for fleet and vehicle wraps, with a print speed of up to 110 m² per hour. It also features a touchscreen panel for easy operation and comes with HP sublimation inks.

4. Mimaki TS100-1600

A more affordable dye sublimation printer, the Mimaki TS100-1600 is ideal for small or home-based businesses. This printer can print directly on fabrics, and although its 70 m² per hour speed isn't as fast as some of the other sublimation printers on this list, it's still an excellent option for those on a budget.

The Mimaki TS100-1600 comes with sublimation inks, RIP software, and output profile software for easy printing.

5. Mitsubishi CP-D70DW

The Mitsubishi CP-D70DW sublimation printer is an excellent option for those who prefer features over affordability. As one of the largest sublimation printers on the market, it can print up to 300 x 300 dpi, making it perfect for high-quality prints.

The Mitsubishi CP-D70DW also has a sublimation speed of up to 430 prints per hour, making it one of the fastest sublimation printers available. However, the lack of physical controls or memory card slots can be a bit of a downside.

Read our guide on the best dye sublimation printers to find the best printer for your needs.

Designs That Pop with Sublimation Printing

Usually, dramatic, quirky, and even ridiculous designs wouldn't be possible with other printing processes. But sublimation printing makes it easy to achieve these designs with its all-over printing capabilities.

Sublimation printing is a great way to add personality to your products and stand out from the competition.

Repeated designs are another great way to use sublimation printing. Since sublimation printing doesn't require a plate for each color, creating designs with multiple colors is easy without incurring high setup costs.

Finally, if you want photography or other images printed on your products, sublimation printing is one of the best ways to do it. The printing process ensures that images are sharp and vibrant, with true-to-life colors.

Designs That Flop with Sublimation Printing

While sublimation printing is excellent for many types of designs, some don't work well with the printing process.

Designs with large areas of solid color or designs with very fine details don't print well with sublimation. This is because such designs have to be excruciatingly accurately placed on the transfer paper, which is then transferred onto the product.

This process can be very time-consuming and often results in subpar prints. Avoid sublimation printing for these types of designs unless you're willing to put in the extra time and effort to ensure they're done right.

Wrapping Up

All in all, sublimation printing is a great printing process for a wide variety of products and designs. Sublimation printing is worth considering if you're looking for a way to make your products stand out.

Remember that sublimation printing isn't the right choice for every design, so take the time to assess whether or not your design is a good fit for the printing process.

Read our comprehensive guide about the best sublimation printers for beginners to learn more!